How to assemble a PTFE hose end?

NUKE PERFORMANCE FULL FLOW PTFE HOSE END FITTINGS ASSEMBLY

How to assemble PTFE hose ends?

In this illustrated guidé you can follow the eight steps on how to assemble a PTFE (Teflon) hose end to a fuel hose with a PTFE inner liner. Following a few simple steps and you are set, but we recommend you get your hands on some simple tools before getting started.

Should I use a PTFE fuel hose setup?

The PTFE fuel hose has many benefits, which we go through later in this description, but the quick answer is Yes. Longer life span, wider working temperature range, safe to use with all types of fuels including ethanol, and for all types of serious motorsports applications. We always recommend a PTFE (Teflon) fuel system for your aftermarket fuel system.

Easy 8-step guide on how to assemble your fittings!

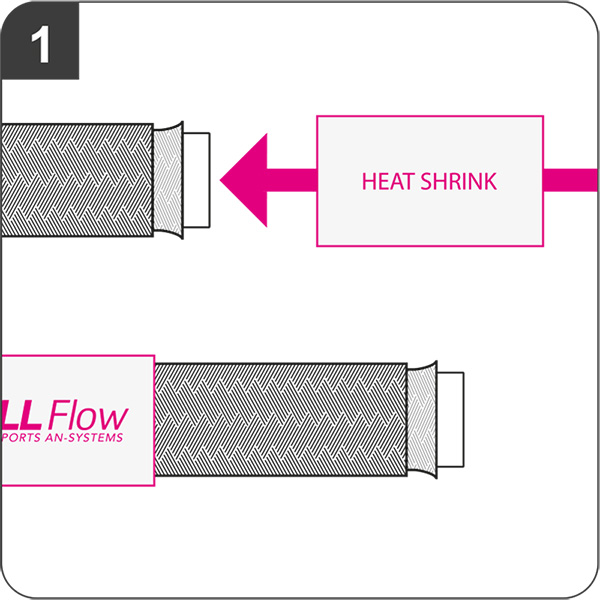

STEP ONE

ADDITIONAL HEAT SHRINK :

For optimal function and finesse, use the associated heat shrink tubing at each hose end. The heat shrink prevents the nylon braiding from threading up and you retain optimal function, appearance, and serviceability.

Additional AN-6/8/10 PTFE heat shrink Part # : 810-21-018

Additional AN-12 PTFE heat shrink Part # : 820-21-022

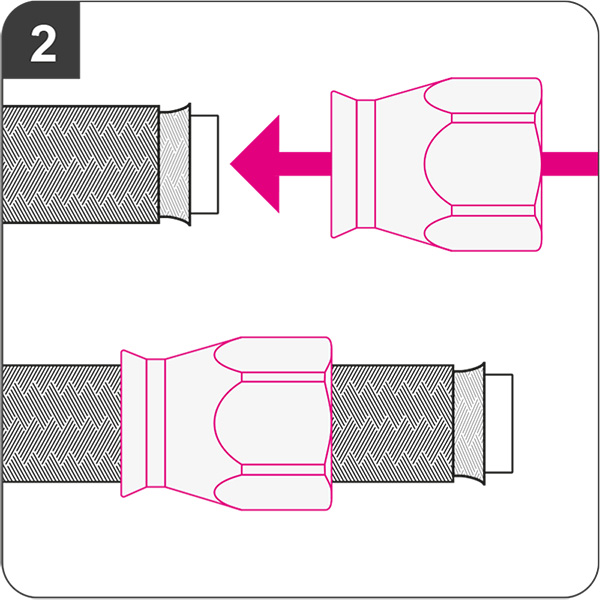

STEP TWO

ALUMINUM HOSE END SOCKET :

Start with putting the aluminum hose end socket onto the PTFE fuel hose. The OD of the fuel hose and the ID of the socket leave no space for margins. Make sure to secure the fuel hose braiding before putting the hose end socket on. If needed, add some grease or lubricant to the inside of the socket to minimize friction. Use Nuke Performance fuel hose for optimal fitment.

Spare Hose End Socket Part # : 810-20-206/208/210/212

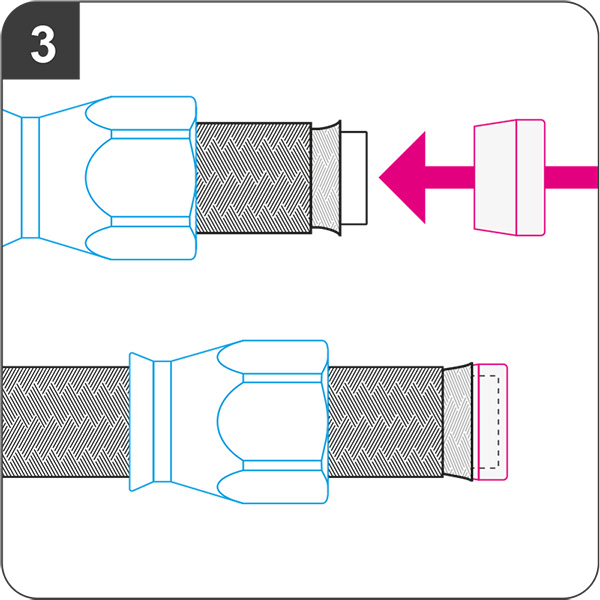

STEP THREE

ALUMINUM OLIVE INSERT :

Locate the included aluminum olive insert so it covers the PTFE inner liner and so the liner goes all the way to the collar of the olive. If you do not have room in between the stainless steel braiding and the liner, use a flat metal tool to widen the stainless steel braiding slightly. The fitment of the olive insert is crucial. If needed, AN-6/8/10/12 spare olive inserts are available.

Spare Aluminum Olive Insert Part # : 810-20-106/108/110/112

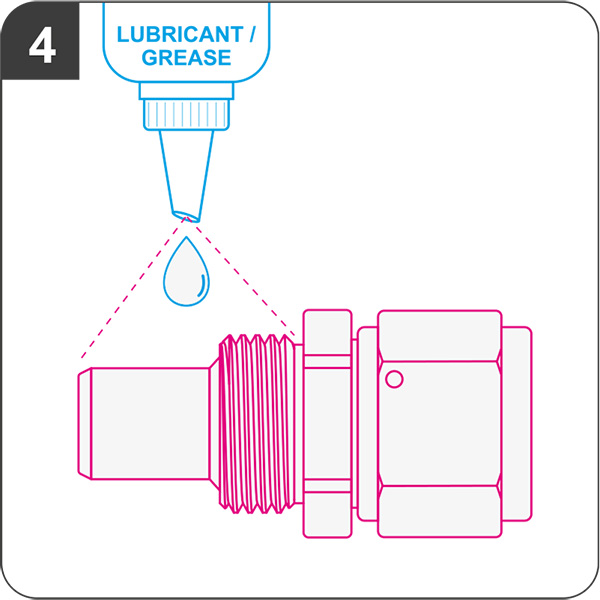

STEP FOUR

USE LUBRICANT OR GREASE :

Before full assembly of the hose end, lubricate the insert and the thread of your hose end body. Use any type of grease that is water-resistant. The lubricant will significantly facilitate the assembly of a PTFE hose end.

Make sure to cover both threads and insert with some kind of lubricant.

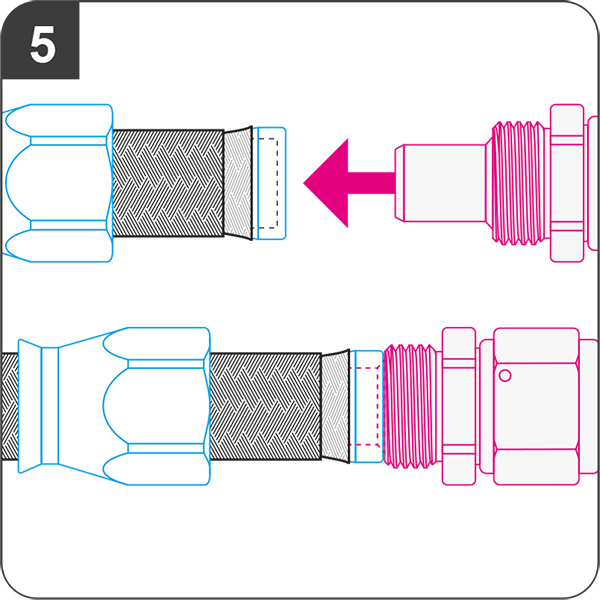

STEP FIVE

PUSH IN ASSEMBLY :

Mount the hose end into the fuel hose and the mounted aluminum olive insert. Make sure to prevent the PTFE liner to deform, but use the amount of force required to make the hose end body and fuel hose fully connected. The aluminum olive face should go all the way to the collar of the hose end body. Note that without any type of lubrication of the fitting, this operation will be hard to execute.

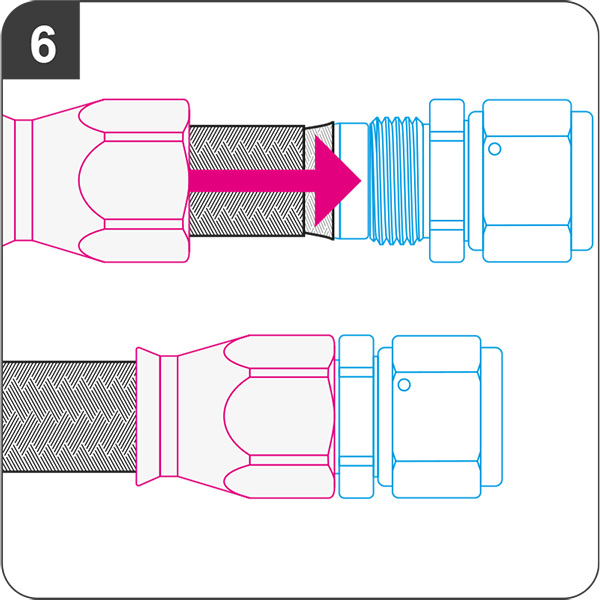

STEP SIX

HOSE END SOCKET ASSEMBLY :

The already mounted hose-end socket threads back on the hose end thread. If there is threaded nylon or stainless steel braiding covering the thread, remove the threads with a scissor and or nipper to give room. Use our assortment of aluminum wrenches, aluminum vise jaws, and handy tools for easy assembly without scratching the aluminum fittings. Use lubricant to the thread.

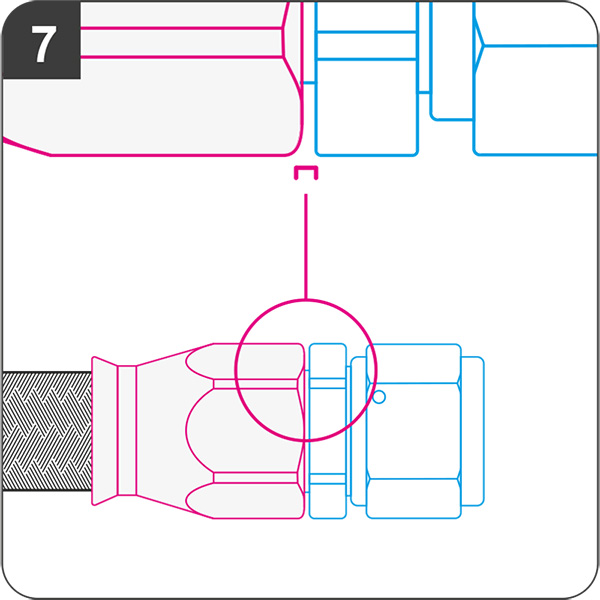

STEP SEVEN

DO NOT OVERTIGHTEN :

When tightening the hose end socket to the hose end body, do not overtighten. A simple guideline is to leave enough space for you to be able to push a fingernail in between the socket and the hose end body.

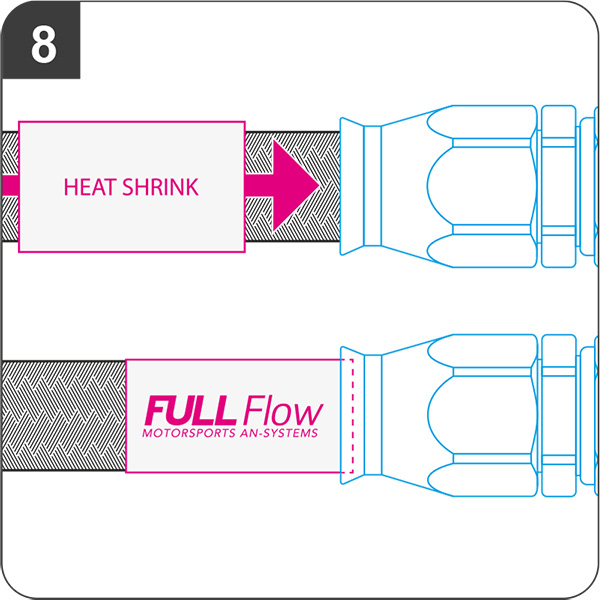

STEP EIGHT

POSITION THE ADDITIONAL HEAT SHRINK

Position the heat shrink to the end of the fuel hose, trying to get it under the edge of the coupling if possible for maximum function. Shrink the heat shrink with a heat gun or other heat source. Never expose a fuel hose to an open flame, especially to a fuel hose assembly that has already been exposed to any kind of fuel.

Take notice of! Make sure to test your fuel system before use, check for any leakage and steady pressure before turning the engine on after building your new fuel setup.

Always use extra care when handling any type of fuel!

Ready to race!

FAQ - PTFE Fuel hose and hose ends

Frequently asked questions about PTFE!

Many of our customers have questions about the PTFE series, and how and if to use it or going with the traditional rubber fuel hose. We have gathered a few of the most common questions and will add more over time. If you have any further questions, contact us for more info.

Why should I run with Nuke Performance Full Flow PTFE series hose ends and fuel hose?

Here you will find some explanations as to why you should choose a fuel hose with a PTFE liner instead of a traditional nitrile or rubber fuel hose. If you have any further questions, that you can´t find answers to on this page, contact us for more information.

Why should I run with PTFE instead of a traditional nitrile or rubber fuel hose?

The Nuke Performance Full Flow series offers a wide selection of PTFE hose ends and fuel hoses. This PTFE series is a perfect solution for all types of fuels, including alcoholic fuels such as ethanol. The PTFE liner acts as a vapor barrier when running all type of fuels, but this comes extra handy when running alcoholic fuels which otherwise often goes through traditional nitrile or rubber fuel hose. Perfect for fuel hoses running within the driver´s compartment, but also for your workshop.

The PTFE fuel hose from Nuke Performance has a much longer life span as it won´t degrade as usual nitrile rubber fuel hose does over time. This protects your injectors, fuel filters, and also in the long run your fuel pumps from getting jammed and harmed by the dissolved inside of nitrile fuel hoses. The Nuke Performance PTFE fuel hose is carbonized for conductivity, this is crucial for fuel systems for motorsports.

The Nuke Performance Full Flow series is the best choice for those who want to build an aftermarket fuel system, especially with components from the motorsports range from Nuke Performance.

What are the benefits of the PTFE fuel hose?

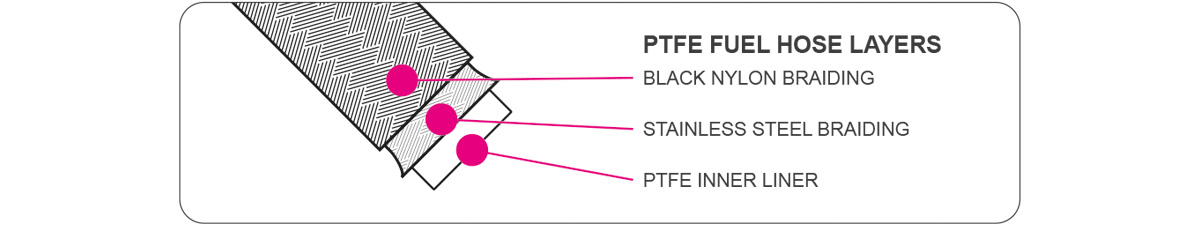

The Nuke Performance Full Flow PTFE lineup uses a full-flow design that lets you design your fuel system with minimum flow loss. And with the three-layered design, it has a much smaller outer diameter than an ordinary nitrile fuel hose. The PTFE liner prevents the fuel hose from hardening and does not fracture or crack. This helps to prevent fuel leakage and the smell of fuel that will occur when running nitrile fuel hose.

The Nuke Performance PTFE fuel hose has a wide working temperature range of -70°C to 250°C (-94°F to 480°F).

What type of fuels do the PTFE fuel hose and hose ends work with?

The Nuke Performance Full Flow fuel hoses with a PTFE inner liner and the matching hose ends are developed for a wide range of fuels. When running alcoholic fuels, traditional fuel hoses made out of nitrile gets damaged after only a short time and for us, the obvious choice is to run a PTFE fuel hose when building a race or motorsports an aftermarket fuel system.

Is the PTFE fuel hose safe to use with alcoholic fuels?

Yes, the Nuke Performance Full Flow PTFE fuel hose is perfect to use with alcoholic fuels such as ethanol (E85), methanol and race fuels for all types of motorsports applications.

Is the PTFE fuel hose safe to use with petrol/gasoline?

Yes, the Nuke Performance Full Flow PTFE fuel hose is perfect to use with gas/petrol and will have a much longer life span than traditional nitrile or rubber fuel hoses.

Can I use the PTFE fuel hose for oil, water, brake fluids, and more?

The Full Flow series PTFE fuel hose from Nuke Performance is perfect to use for brake, clutch, coolant, power steering, transmission, and water.

In what sizes can I find PTFE hose ends?

The Nuke Performance Full Flow PTFE hose ends is available in a wide variety of sizes and setups, AN-6, AN-8, AN-10, and AN-12. They are available in Straight, 30°, 45°, 60°, 90°, 120°, 150°, and 180° versions. View our selection of hose end fittings below. Available from worldwide dealers, distributors, and also online at www.nukeperformance.com.

In what sizes can I find a PTFE fuel hose?

The Nuke Performance Full Flow PTFE black nylon fuel hose is available in several sizes, from AN-6 to AN-12. All fuel hoses are delivered in pre-cut length and available in custom, longer length on demand. Available from worldwide dealers, distributors, and also online at www.nukeperformance.com.

Does a PTFE fuel hose have a longer life span than a nitrile fuel hose?

A PTFE fuel hose withstands fuel of any kind better than a traditional fuel hose, but especially when running alcoholic fuels which have a destructive force against rubber and nitrile fuel hoses. The PTFE liner prevents malfunction, leakage, cracks, and in the long run preventing serious danger when you may get leakage within your high-pressure fuel system. If fuel leakage isn´t noticed directly, your vehicle could catch on fire, simply due to the heat of your engine, exhaust, etc.

What is a PTFE fuel hose? And what is the difference from a traditional fuel hose?

The Nuke Performance Full Flow PTFE fuel hose has an internal liner out of PTFE (Teflon) instead of a rubber/nitrile core such as the one you find in an ordinary fuel hose. The Teflon liner is much thinner than the rubber hose, but at the same time, it also withstands much higher pressure (up to 10000 PSI for the AN-6 fuel hose) and also withstands the destructive force of fuel, especially those in alcoholic fuels. The Nuke Performance Full Flow series fuel hose also uses stainless steel braiding, and also an external black nylon braiding.

Nuke Performance Full Flow series PTFE hoses and hose ends

Nuke Performance Full Flow PTFE fuel hoses

-

from € 46,25

-

from € 57,50

-

from € 32,50

-

from € 36,25

-

from € 11,88

-

from € 16,25

Nuke Performance Full Flow PTFE hose ends AN-6

-

€ 15,00

-

€ 33,75

-

€ 33,75

-

€ 33,83

-

€ 33,88

-

€ 35,00

-

€ 35,13

-

€ 35,13

Nuke Performance Full Flow PTFE hose ends AN-8

-

€ 15,75

-

€ 37,25

-

€ 37,25

-

€ 37,25

-

€ 37,25

-

€ 39,00

-

€ 39,00

-

€ 39,00

Nuke Performance Full Flow PTFE hose ends AN-10

-

€ 19,25

-

€ 39,00

-

€ 39,00

-

€ 39,00

-

€ 39,00

-

€ 40,75

-

€ 40,75

-

€ 40,75

Nuke Performance Full Flow PTFE hose ends AN-12

-

€ 26,00

-

€ 48,63

-

€ 48,63

-

€ 48,63

-

€ 48,63

-

€ 53,13

-

€ 53,13

-

€ 53,13

Nuke Performance Tools for Hose ends and Fittings

-

€ 80,00

-

€ 40,00

-

from € 25,25

-

from € 4,00